- Kami memberikan line product terlengkap dari berbagai ukuran, jenis, kualitas dan merk

- Kami memberikan line product terlengkap dari berbagai ukuran, jenis, kualitas dan merk

- Kami memberikan line product terlengkap dari berbagai ukuran, jenis, kualitas dan merk

- Kami memberikan line product terlengkap dari berbagai ukuran, jenis, kualitas dan merk

- Kami memberikan line product terlengkap dari berbagai ukuran, jenis, kualitas dan merk

- Kami memberikan line product terlengkap dari berbagai ukuran, jenis, kualitas dan merk

- Kami memberikan line product terlengkap dari berbagai ukuran, jenis, kualitas dan merk

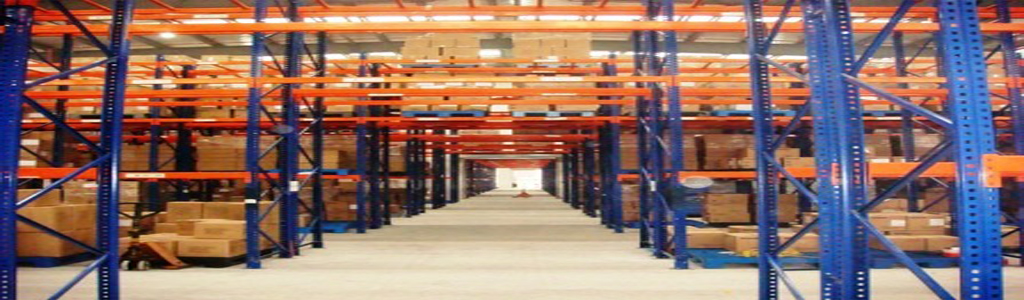

- Sistim manajemen profesional di segala sisi, memberikan pelayanan terbaik kepada customer

- Sistim manajemen profesional di segala sisi, memberikan pelayanan terbaik kepada customer

- Sistim manajemen profesional di segala sisi, memberikan pelayanan terbaik kepada customer

- Sistim manajemen profesional di segala sisi, memberikan pelayanan terbaik kepada customer

- Sistim manajemen profesional di segala sisi, memberikan pelayanan terbaik kepada customer

- Sistim manajemen profesional di segala sisi, memberikan pelayanan terbaik kepada customer

- Sistim manajemen profesional di segala sisi, memberikan pelayanan terbaik kepada customer

- Sistim manajemen profesional di segala sisi, memberikan pelayanan terbaik kepada customer

Copyright (c) 2012, PT. Union Tetap Jaya. All rights reserved

C. B-14

KAWAT LAS - KOBE STEEL

1. WELDING ELECTRODES FOR CARBON STEEL

Applications

Shielded metal arc welding of heavy-duty structures as ships, vehicles, buildings and bridges

made of mild steel. For all-position welding of heavy-duty structures.

Characteristics on usage

B-14 is an ilmenite type covered electrode designed for better usability and weld ability. It is

suitable for butt or fillet welding in all positions for thin or thicker plate (1.6 to 2.0mm).

In horizontal fillet welding, slag covering and bead uniformity are good and bead appearance

is beautiful.

Its usability in vertical or overhead welding is best among ilmenite type electrodes.

Due to good X-ray soundness and mechanical properties, B-14 is used for skill testing and

competition by choice.

Notes on usage

Pay attention not to exceed the range of proper currents. Welding with excessive current not

only lower X-ray soundness, but also causes increase of spatter, undercut and insufficient

slag covering.

Dry the electrodes at 70-100� C for 30-60 minutes before use. Excessive moisture absorption

lower usability and may result in some porosities.

Excessive drying before use causes less penetration and overheating of the electrode.

Medium or heavy thick plate should be welded under proper preheating and interpass

temperature.